FRN0007E2S-4GB (FUJI MAKE)

The FRN0005C2S-4A is a standard type inverter developed by Fuji Electric for reliable and efficient control of industrial motors. Designed for 3-phase 400V input, it delivers an output power of 1.5 kW, making it suitable for medium-scale motor control applications in manufacturing, automation, and process industries. As a part of Fuji’s main body series and current product lineup, this model is engineered for global use, supporting installations in various regions including Asia. It offers stable operation, advanced motor control features, and energy-saving capabilities in a compact, easy-to-integrate form.

Control Inputs/Outputs

Qty 5 Digital Inputs: X1 – X3, FWD, & REV Programmable, 21 Selectable Functions Qty 2 Analog Inputs: Qty 1 – 0 to +10Vdc & Qty 1 – 4 to 20mA Qty 2 Digital Outputs: Qty 1 Form C Relay & Qty 1 Transistor, 23 Selectable Functions Qty 2 Analog Output: Selectable Type: 0 to 10Vdc or 4 to 20mA, 43 Selectable Proportional Output Signal Functions Qty 1 RS-485 Connections: RJ45 Port Operator’s KEYPAD having LED Display Indicating System Operation and Associated Unit Conversion Displayed Keypad indication of Operations, Number of times unit placed in operation, Duration and kWh output 24Vdc Output Terminal: 50mA Maximum Supply

Fully Compatible with Existing Products (FRENIC-Mini C1)

External Dimensions: Interchangeable Installed Dimensions: Interchangeable Number of Terminals: Same for both main circuit and controllers Terminal Position: Compatible terminal with length Function Codes: Compatible function codes Built-In RS-485 Communication: Shared communication protocol

Flexibility

FRENIC-Mini Keypad Displays Speed, Current, Frequency or Voltage output, PID operating data, Configurable to indicate process operating units Optional USB keypad PC Programming Loader Software Easier Maintenance Data: Mock malfunction, Number of startup, Cumulative motor running time, Total power, Trip history etc. Automatic Energy Savings Control: Optimum control of drive and motor loss PID Controller with Sleep mode, Proportional, Integral & Differential parameter settings to maximize control Cooling Fan ON/OFF control function V/F non-linear 3 step settings 2 Motor switch control Brake signal Rotation direction control Single phase Input models are available Synchronous Motor control

Motor Control

PM Motor Control Capability

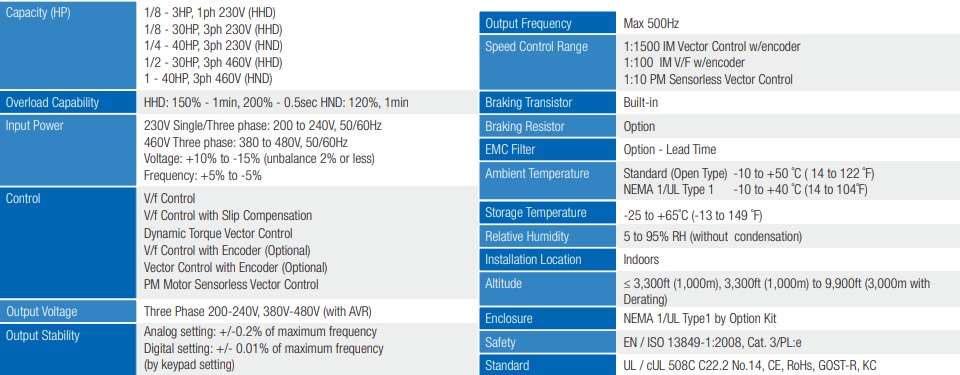

Control: V/F control, Slip compensation,

Auto-toque boost, Dynamic torque vector

control system

Rating: 150% for 1 min

200% for 0.5 se

Safety and Standard

EN61800-5-1 (Low Voltage Directive)

UL 508C, CE

Optional NEMA/UL Type 1 Kit

RoHS Directive Compliance