FRN0002C2S-4A

The FRENIC-Mini (C2) is our newest generation inverter and is fully compatible with the previous model (C1), offering extended horsepower (up to 20HP) in a compact design. Our most user-friendly drive yet, the performance of the FRENIC-Mini (C2) has been improved and comes standard with RS-485, torque vector control, permanent magnet motor, and PID control. This rich functionality is coupled with a compact design for a superior user experience, and customers will enjoy the ease-of-operation and global compatibility. The new FRENIC-Mini elevates the performance of a wide range of devices and equipment including conveyors, fans, pumps, centrifugal separators, and food processing machines. Its capabilities give you the system integration, energy efficiency, reduced labor, and lower overall costs for which you are looking.

Control Inputs/Outputs

Qty 5 Digital Inputs: X1 – X3, FWD, & REV Programmable, 21 Selectable Functions Qty 2 Analog Inputs: Qty 1 – 0 to +10Vdc & Qty 1 – 4 to 20mA Qty 2 Digital Outputs: Qty 1 Form C Relay & Qty 1 Transistor, 23 Selectable Functions Qty 2 Analog Output: Selectable Type: 0 to 10Vdc or 4 to 20mA, 43 Selectable Proportional Output Signal Functions Qty 1 RS-485 Connections: RJ45 Port Operator’s KEYPAD having LED Display Indicating System Operation and Associated Unit Conversion Displayed Keypad indication of Operations, Number of times unit placed in operation, Duration and kWh output 24Vdc Output Terminal: 50mA Maximum Supply

Fully Compatible with Existing Products (FRENIC-Mini C1)

External Dimensions: Interchangeable Installed Dimensions: Interchangeable Number of Terminals: Same for both main circuit and controllers Terminal Position: Compatible terminal with length Function Codes: Compatible function codes Built-In RS-485 Communication: Shared communication protocol

Flexibility

FRENIC-Mini Keypad Displays Speed, Current, Frequency or Voltage output, PID operating data, Configurable to indicate process operating units Optional USB keypad PC Programming Loader Software Easier Maintenance Data: Mock malfunction, Number of startup, Cumulative motor running time, Total power, Trip history etc. Automatic Energy Savings Control: Optimum control of drive and motor loss PID Controller with Sleep mode, Proportional, Integral & Differential parameter settings to maximize control Cooling Fan ON/OFF control function V/F non-linear 3 step settings 2 Motor switch control Brake signal Rotation direction control Single phase Input models are available Synchronous Motor control

Motor Control

PM Motor Control Capability

Control: V/F control, Slip compensation,

Auto-toque boost, Dynamic torque vector

control system

Rating: 150% for 1 min

200% for 0.5 sec

Safety and Standard

EN61800-5-1 (Low Voltage Directive)

UL 508C, CE

Optional NEMA/UL Type 1 Kit

RoHS Directive Compliance

Warranty

3 years from date of shipment

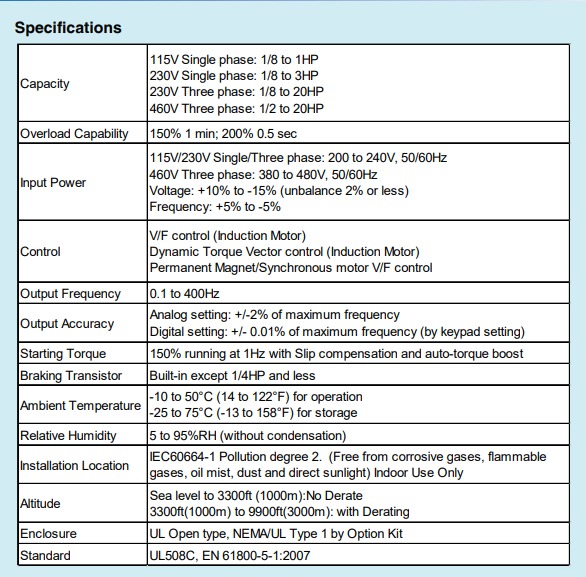

General Specifications

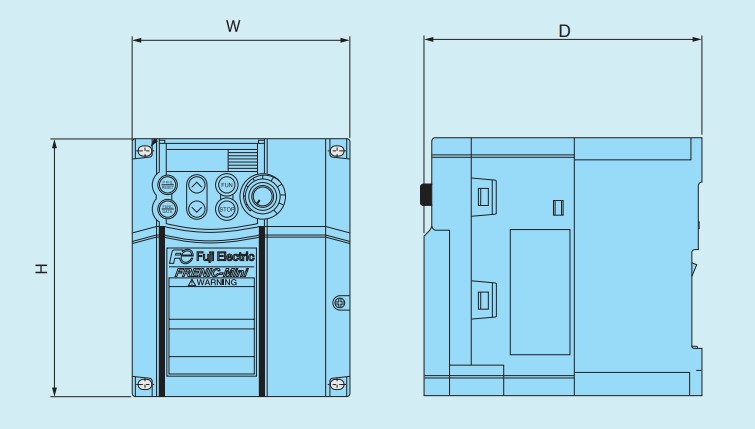

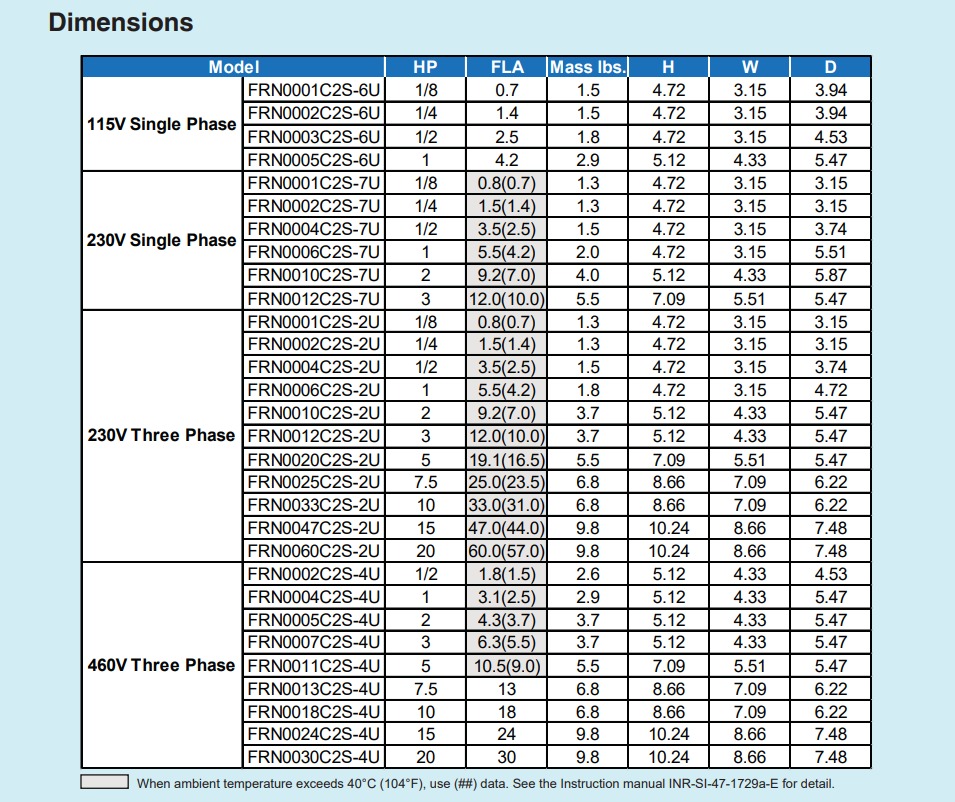

Dimensions

Options

- NEMA/UL Type1 Kit

- DIN Rail Adapter (5HP and Less)

- DB Resistor (1/2HP and Above)

- USB Keypad

- CE Filter