Application Brief:

This Is Production Traceability System, here we are logging the process values for QC purpose with reference to the serial number of each engine assembly. We are also providing interlocking for the process control where ever required.

Customer Requirements:

- Customer Need a complete solution.

- Need to accommodate different protocols with the same system .

- Logging of process data directly to server.

- Logging of data in plc when the server is down up to 24hrs.

Impact:

- Customer very much satisfied with this complete solution .

- FB based SQL Programming makes comfortable for maintenance engineer to handle the program during trouble shooting.

- Customer can able to get the process data even server is down.

Advantage :

- FB & STL programming reduced development Time.

- Displaying Images During Error in HMI is so interactive.

- Direct Communication with field device like nut-runner, Air-leak tester, bar code scanners, Servo press etc.

Key Points to Success:

- Technical Support During Design & Installation.

- Online SQL server communication demo provided at site during initial stage & build the confidence .

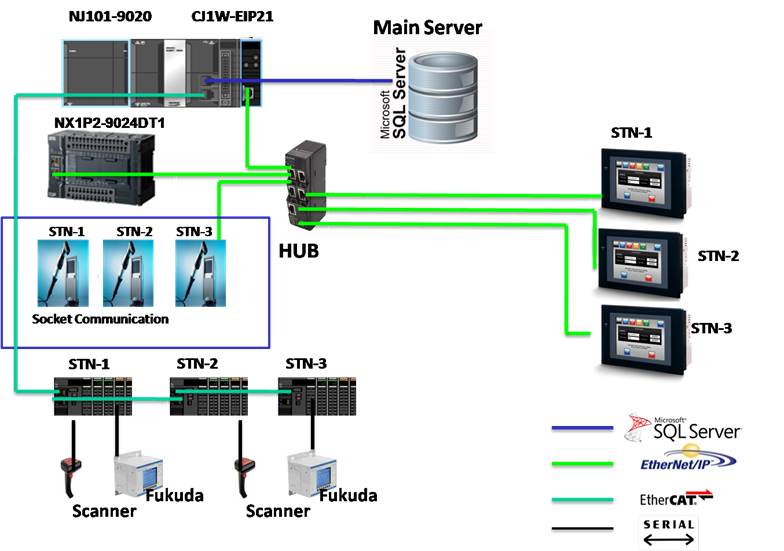

System Architecture: