Project Introduction :

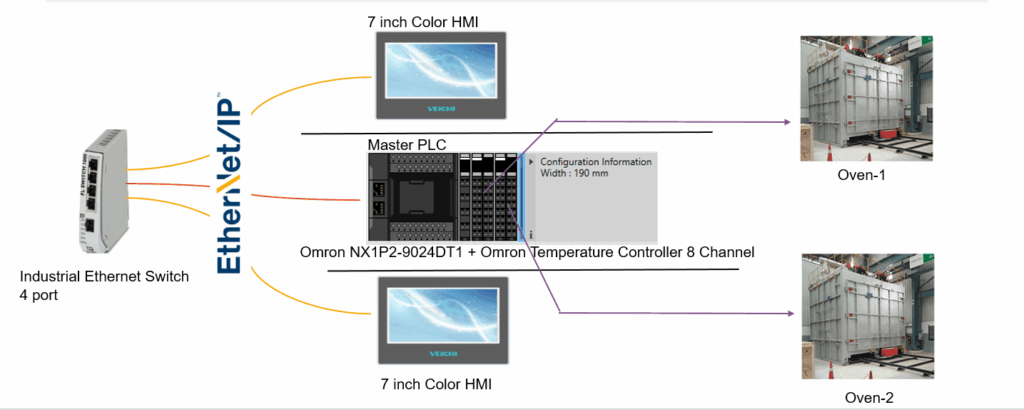

- The oven operation project was developed to systematically and efficiently control and monitor burner ovens using a system of one plc and multiple HMI devices.

- These particular burner ovens are used for drying and solidifying the product used in the winding cylinders of different types of transformers.

- These winding cylinders are used to cover the magnetic core of transformers.

- The temperature of the ovens is maintained and regulated using a series of temperature controllers and fans operated by induction motors.

Description:

- The oven operation project's entire operation is about controlling two gas ovens using a plc with extended inputs( to monitor the temperature of the ovens using K-type temperature sensors) along with two HMIs to control each oven seperately.

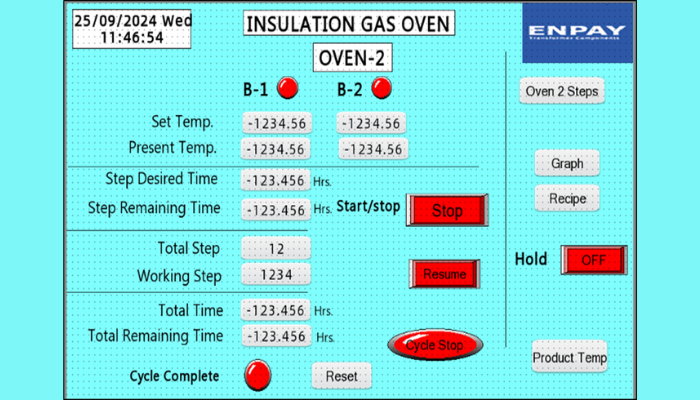

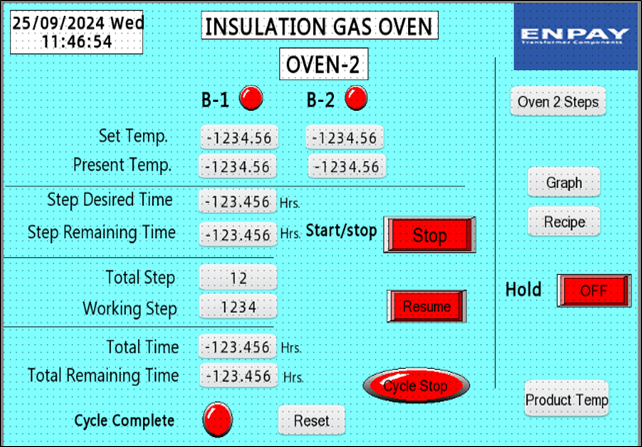

- The main objective of this project is to run an entire cycle of ovens running over certain predefined periods of time maintaining a specified temperature.

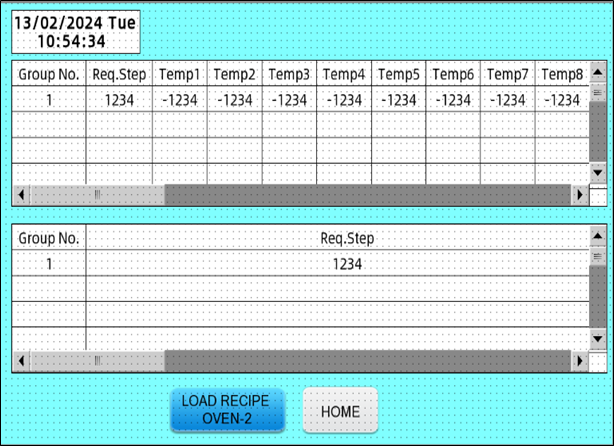

- An operator enters the temperature of the ovens to be maintained over a corresponding time period which together form a step of the cycle.

- The number of steps required for a cycle is determined by an operator through the HMI which also displays the current temperature of the oven and the time left for the cycle to completed.

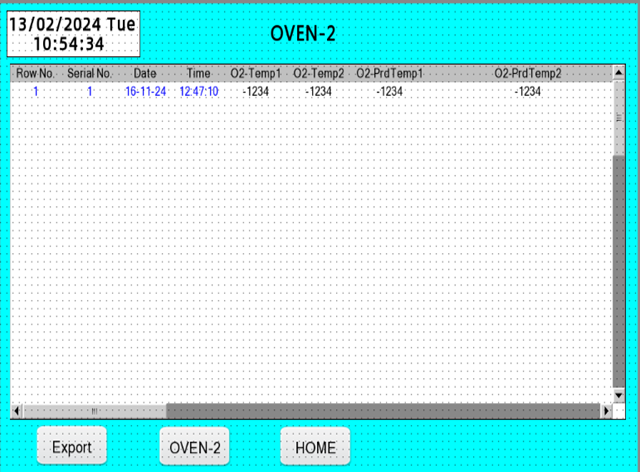

- The HMI for each oven is also used to maintain a data history log which contains the temperature of the oven and the product inside it measured at every 30 minute interval.

User Interface:

Main HMI Screen

Recipe Data

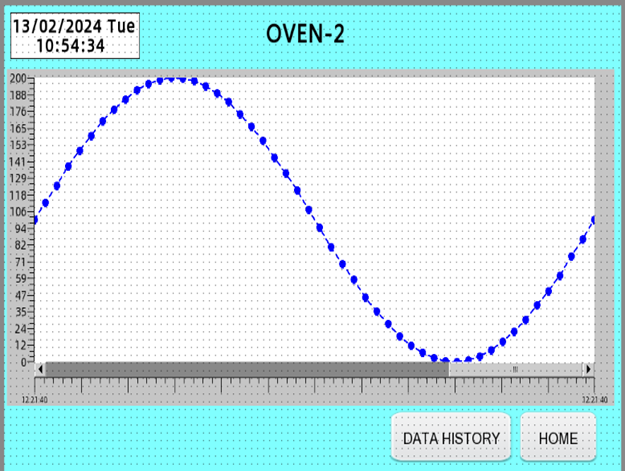

Temperature ->Time Graph

Data History Log

System Architecture: