Project Introduction :

A Mills is a composite textile mill manufacturing worsted fabrics (menswear), paper makers felts and industrial textiles. A Major Textile Company for the felt division in Gujarat.

Our Service include The Project Design, Development & Execution of Industry 4.0 Automation like:- Programmable logic Controller (PLC),Human machine interface (HMI), Supervisory Control and Data Acquisition(SCADA) with ERP Reporting via Database Communication.

Customer Application :

- Loom Machine Operation runs for 3 shifts in a day. So for constant monitoring and controlling the operation has to be managed by 3 Departments ( Manager, Supervisor, Operator).

- For Loom Operation, Operator has to be present on machine during the shift for production purpose.

- If Operator is absent/inactive at loom machine more than 2min or 10min then they need to provide reason for that which has to be logged in the Scada Report.

- Reason can be given by Supervisor or Manager in presence of Operator of the Machine.

- If Machine stops for 2 min then there should be a reason pop-up for the operator to select on HMI.

- Also for Machine Stoppage for over 10mins with Yellow light Indication on the machine & should not be operated until a reason is given by Supervisor or Manager.

- For Reason Selection for over 10min Stoppage, Supervisor or Manager needs to authenticate their finger/face for resuming the machine operation.

- For Breakdown of the Loom Machine there will be is a Red Light Indication.

Implementation:

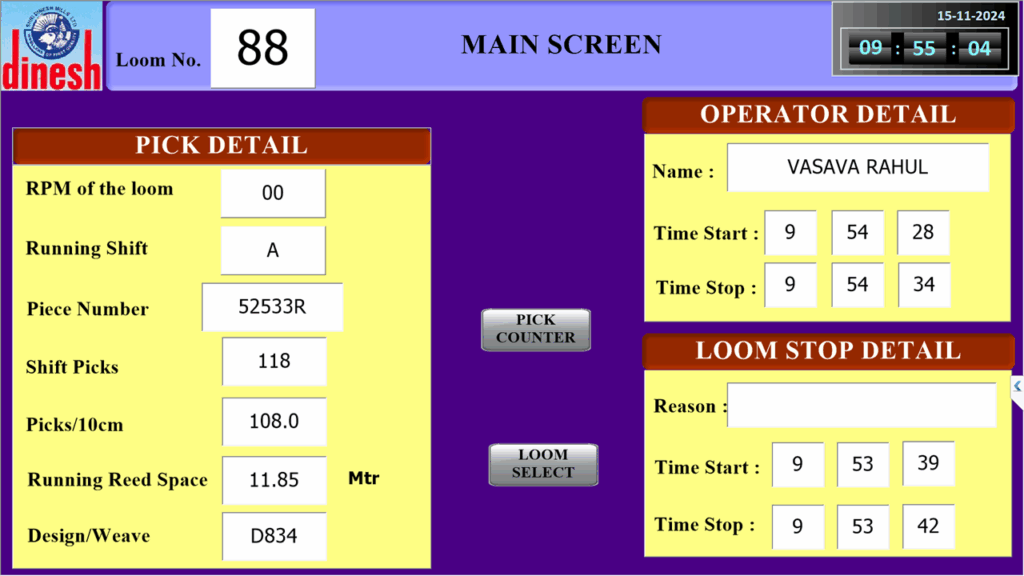

- Loom Machine needs an Operator to operate.

- Operator is present at machine for the production during the shift , and if the operator is not running the machine/absent for 2 mins then they need to provide reason for their absence/inactivity via Panel HMI which will log that data in the Scada Report.

- If Operator is inactive/absent for more than 10mins then the Machine Gets Stopped with Yellow Light Indication. Now to again operate the Machine Operator needs to authenticate his finger/face on the Biometric module and give appropriate reason to Supervisor. Supervisor also needs to authenticate their finger on the biometric module after selecting the Reason and the Machine is ready for operation again.

- This procedure repeats for every 2min/10min stoppage & also if the machine is under breakdown which is a selection given on Panel HMI.

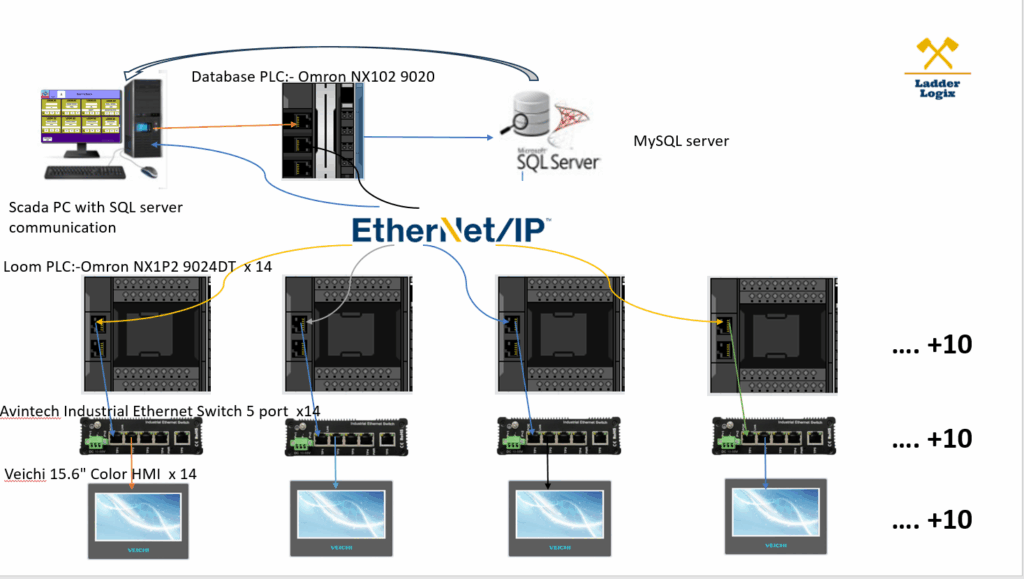

- The Data of the Looms is shared from Loom PLC to MySQLServer by a Database Controller for Reporting/Monitoring.

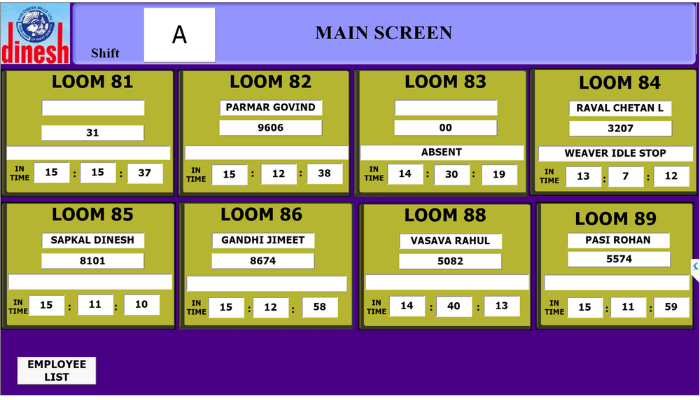

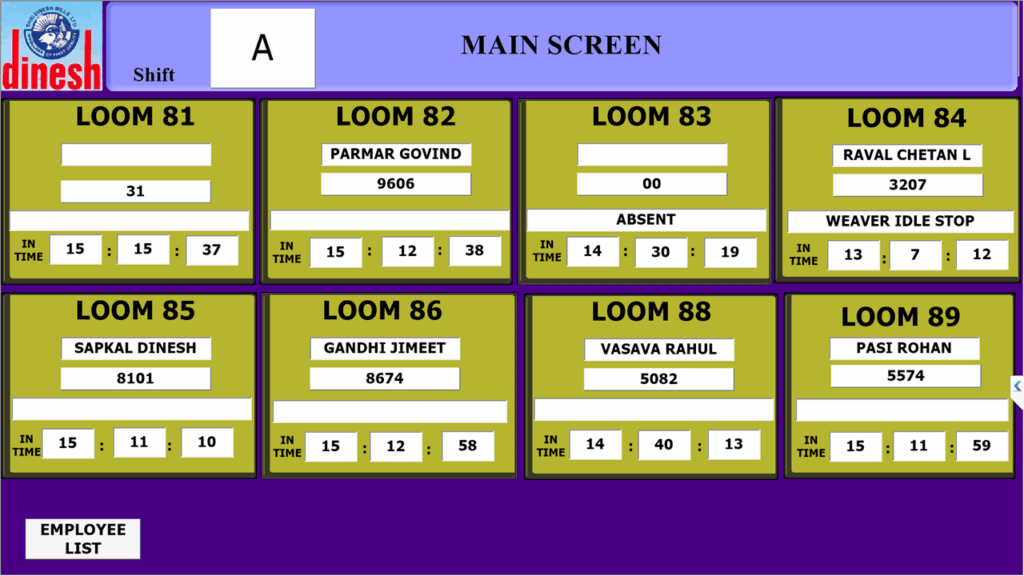

- Looms Details is also displayed on a Monitor PC via Scada Software for each loom Machine.

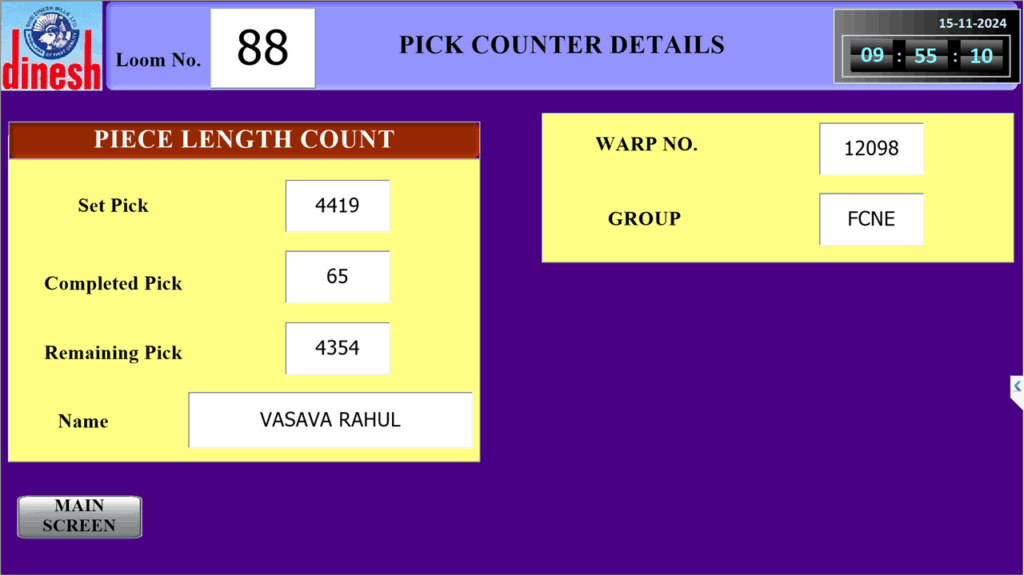

User Interface:

System Architecture:

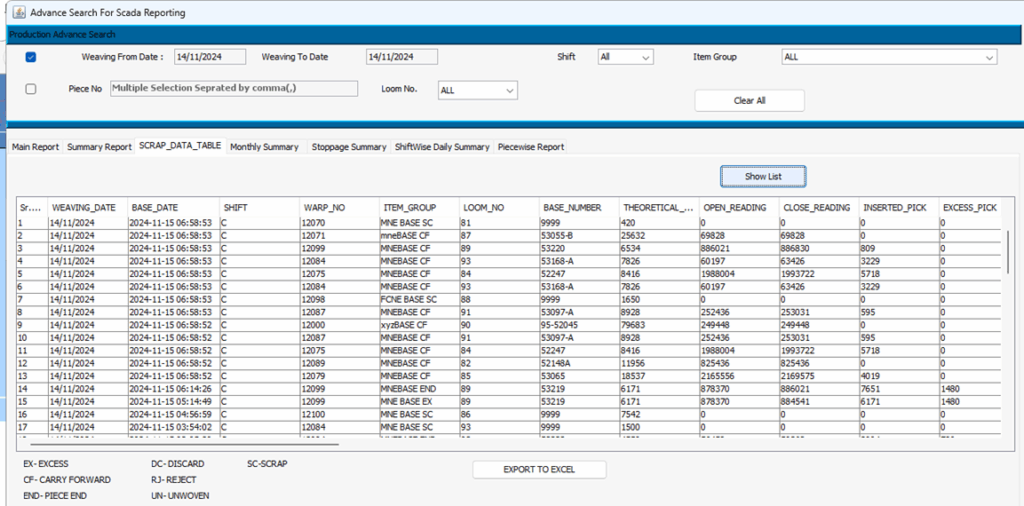

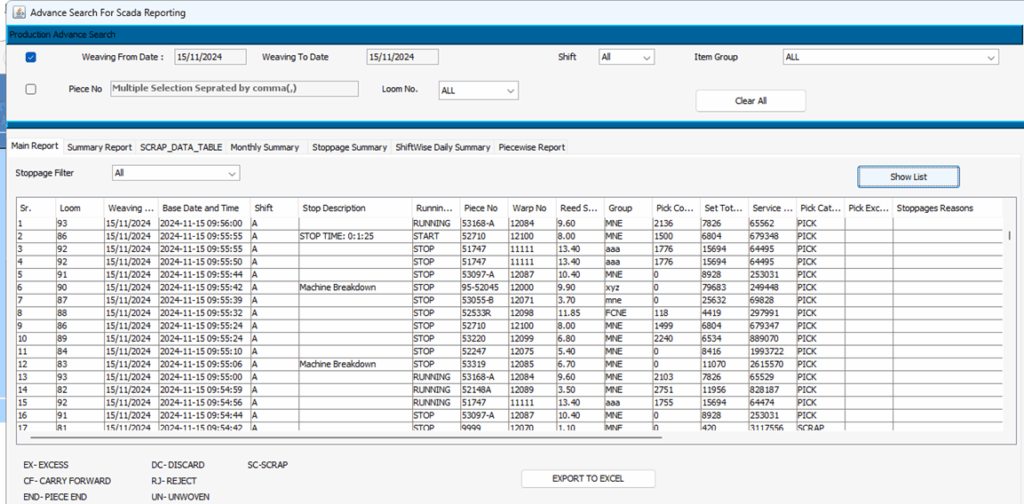

Reports:

Main Report