Project Introduction :

- CAPTAN 50, is a fungicide of micronized particle size for use water as a spray for control of certain fungus diseases of fruit, vegetable seeds and ornamental crops.

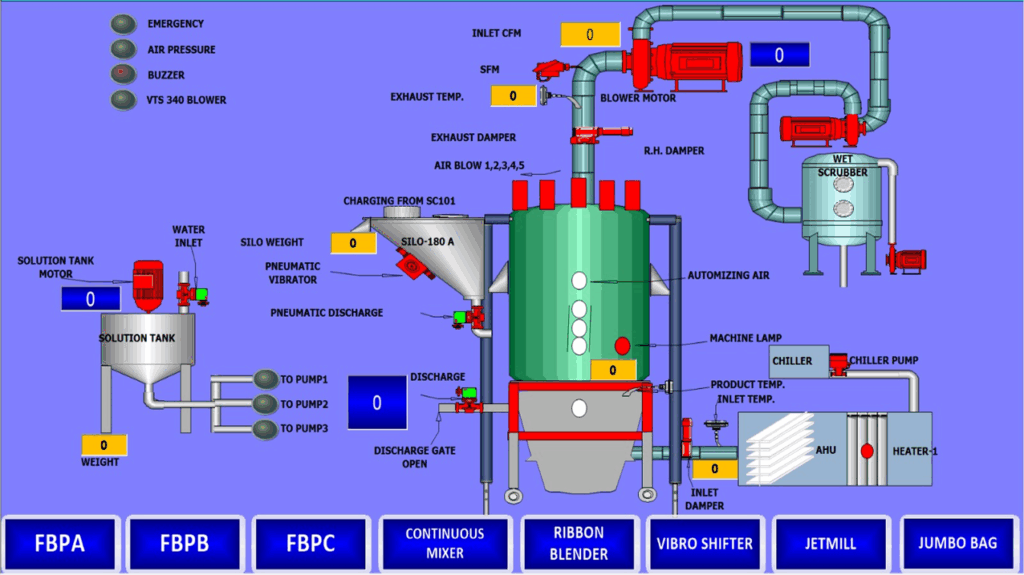

- This project included the manufacturing of captan 50 fungicide with an entire upgrade to the existing hardware along with software update of the PLC program and the development of SCADA . The main objective of this project was to integrate different processes in the manufacturing plant controlled by different PLCs, under one single panel to control the entire operation and to eliminate redundancy issues.

Project Description:

- Ribbon Blender :- It is a specialized mixing machine designed for the uniform blending of powdered and granular fertilizers. It handles nutrient-rich materials, chemical additives, and organic compounds efficiently, ensuring high-quality production for agriculture.

- Continuous Mixer :- This machine’s main purpose is uniform distribution of nutrients like Nitrogen, Phosphorous and Potassium along with precise blending, reduced segregation, increased efficiency, time savings and energy efficiency.

- Jet Mill:- This machine utilize high-velocity gas jets to reduce particle size through collisions and attrition within a milling chamber. The material is fed into a vortex created by jets where particles collide, break apart and are then micronized.

- Vibro Shifter:- This machine is also known as gyratory vibratory sifter, separates particles based on their size and shape using vibrations and gyratory motion . It utilizes a circular screening surface, typically mesh or perforated plates, and a vibratory motor or eccentric weights.

User Interface:

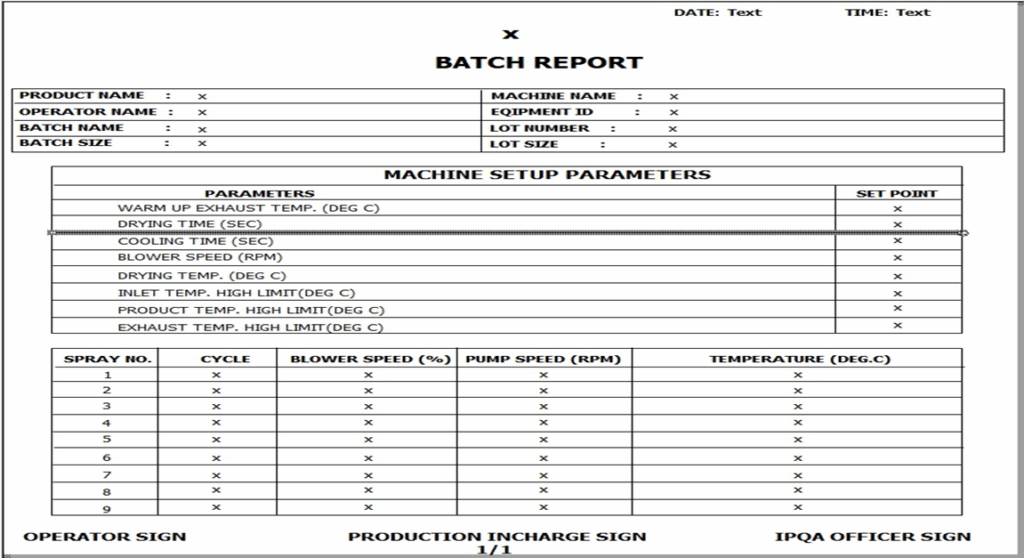

Report: