Detect Project (How to find it?)

One of the cable manufacture of Gujarat who is the leading manufacturer of electrical cables for domestic and industrial use , They need some power control system for Annealing machine .

Key factor (Customer needs and conflict facts)

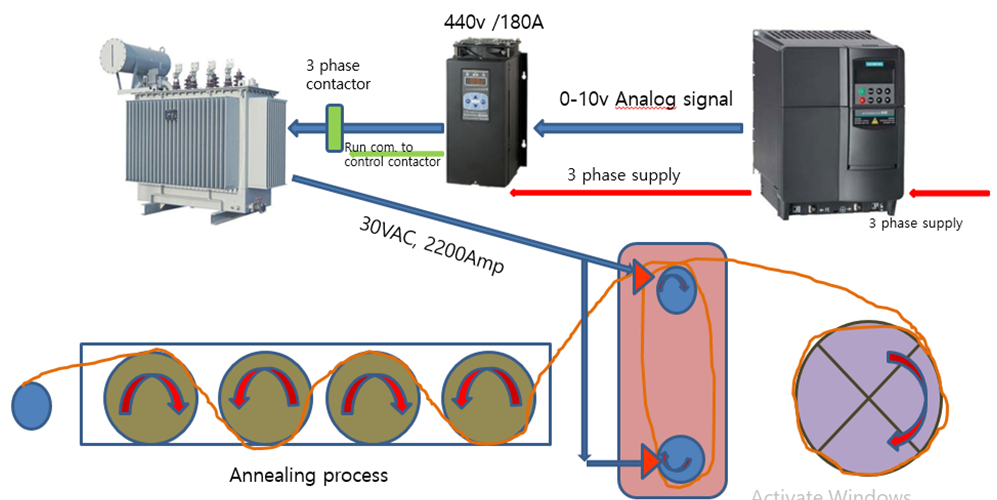

- Customer need some device which control the power going to transformer and the output Voltage & current used to heat the copper wire to restored the wire ductility .

- Because of huge rated transformer in a line we get continuous reverse voltage , and when power switched off reverse current can damage SCR , during setup because of reverse current our fuses get blow out.

Solve the problem (How to settle the conflict?)

- After proper understanding the application , we suggest our thyristor for annealing application , 0-10V Analog signal generated from VFD given to thyristor as the input and according to that power get control I,e at 0v input thyristor firing at 0% power means no heating and 10v input thyristor fire at 100% power mean full heating of wire

- As per application we give 3 phase 440vac, 180amp thyristor with MODBUS communication

- For safety we provide high speed semiconductor fuses and 3 phase contactor in output to avoid reverse current flow from transformer along with this over voltage & current alarm, 30sec soft start, 20 sec slop-down, 10 sec slop-UP set in Thristor to get precise control on power

Conclusion of project

After completing the setup and lot of tuning , annealing system working very smoothly .